AUTOMATED,

SEMI-AUTOMATED &

MANUAL WET BENCHES

Thermco design and manufactures a comprehensive range of wet benches for semiconductor and related electronic manufacturing processes. From simple manual stand-alone R&D applications, to fully automated production wet benches with connectivity to the fab host via SECS/GEM.

WET PROCESSING SYSTEMS

- Clean & Etch

- Pre-diffusion / RCA Clean

- Standard Clean SC1, SC2

- BHF / BOE, QDR

- Ultrasonic, Megasonic,

Agitation - Metal Lift-off

- Porous Si

- Single wafer cleaning

- Electroless metal deposition

Au, Ni, Pd, Cu, Ag - Furnace Tube & Quartzware

Cleaners - MEMS Process Systems

- Bespoke Processes

- Aqueous & Solvent applications

R&D, PILOT PROCESS, VOLUME PRODUCTION

High reliability process solutions for FEOL and BEOL technologies

R&D, PILOT PROCESS, VOLUME PRODUCTION

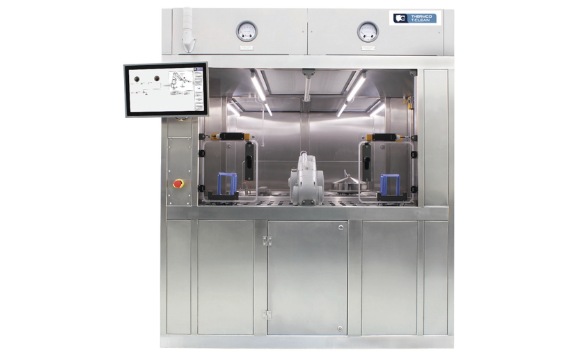

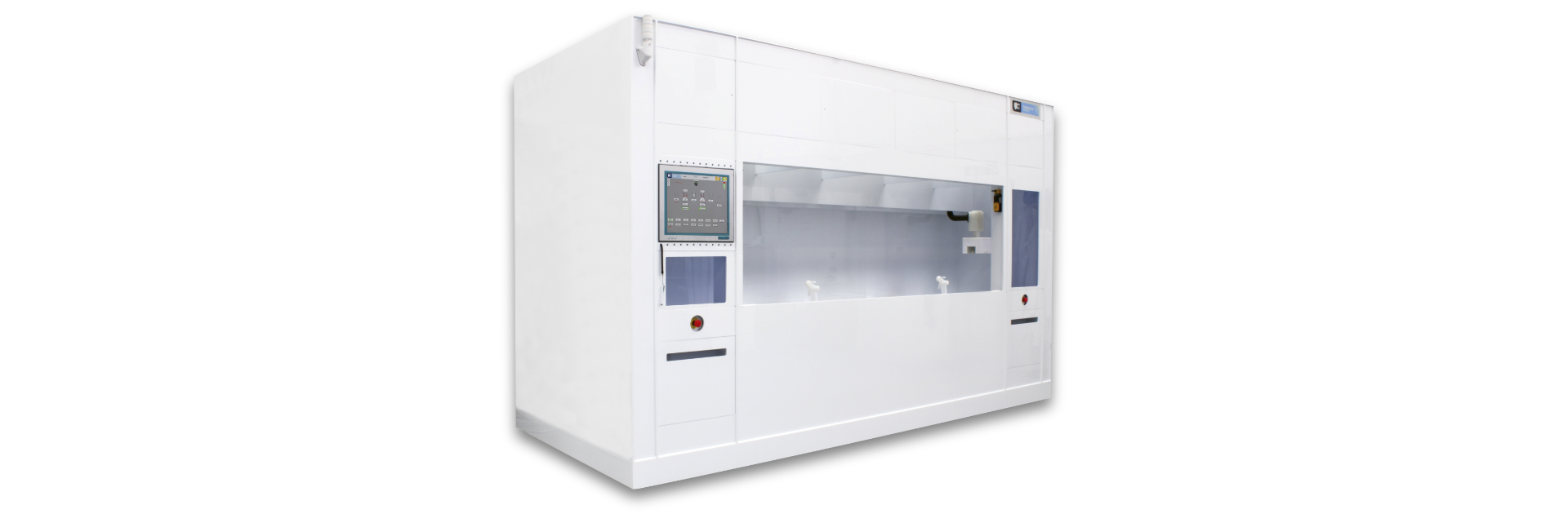

Cassette load-unload processing of 25 – 50 ≤ 300mm substrates. 3-axis ultra-reliable cartesian robot serving multiple processes and rinse baths.

Reduced Surface Tension Dryer or SRD. Multiple recipe settings via HMI with P&ID real-time display and maintenance facility. SCADA based control system with full SECS/GEM interface to fab host.

WET BENCH OPTIONS

Process baths with filtered recirculation, chemical monitoring and dosing control, ultrasonic, mega-sonic, and robotic agitation in a variety of materials including

Polypropylene, Quartz, PVDF, and PFA. QDR with resistivity monitoring & recirculation/weir bath. Glove wash and sample port. Solvent or Aqueous applications, stainless steel or Polypropylene construction, Fire suppression system and FM4910 compliance.

HMI AND CONTROL SYSTEM

PLC-based control system with 64-bit SCADA designed for process control, manufacturing systems and open automation applications. Compatible with the .NET platform and Microsoft operating systems.