VTR6000EX / VTR7000EX CONTROL SYSTEM UPGRADE

OVERVIEW

Thermco introduces the ultimate control system upgrade for existing SVG Thermco VTR 6000/7000 series of vertical furnaces.

The VTR 7000XE uses the latest PC control, hardware and automation technology extending the life of VTR systems and addressing many of the obsolescence issues now faced by these systems.

The VTR 7000XE product is a critical hardware and software upgrade to keep your system running smoothly replacing obsolete process control (PACE), automation (ACE) and communication subsystems.

CONTROL SYSTEM SOLUTIONS

- Increase system lifetime functionality and uptime of existing systems with a fully supported VTR 7000XE upgrade

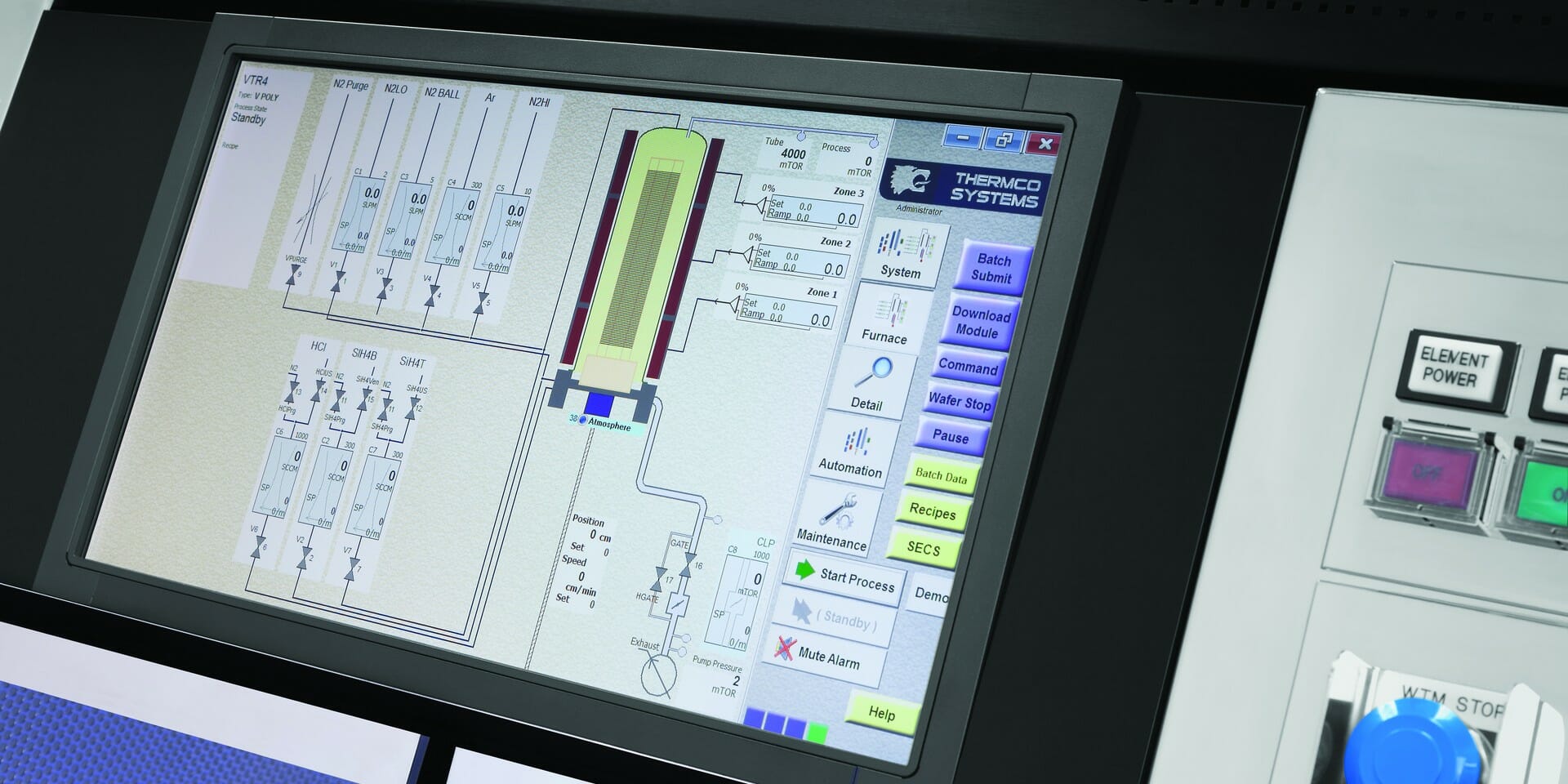

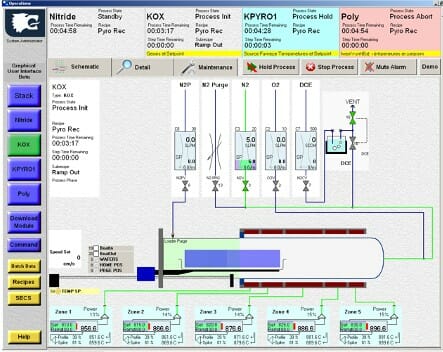

- Modern Windows-based PC control system and touch screen GUI interface for ease of operation, process recipe creation, data collection and charting

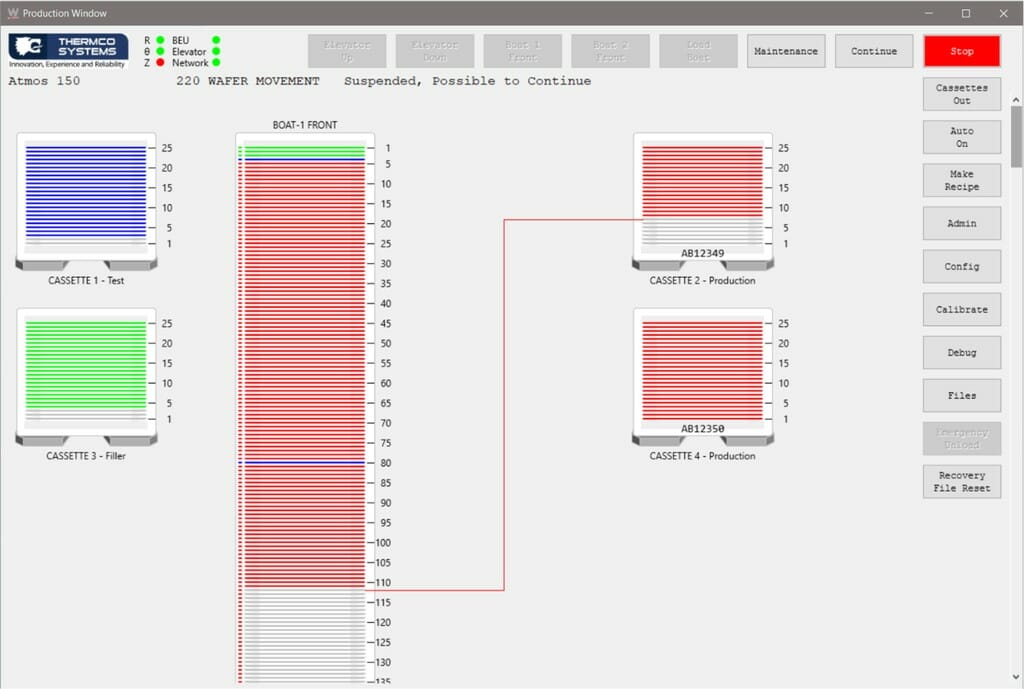

- Advanced robotic interface via the VTR 7000XE GUI control for improved manufacturing and maintenance user experience

- Modern and compact industry standard TMX tube controller replaces obsolete PCE systems

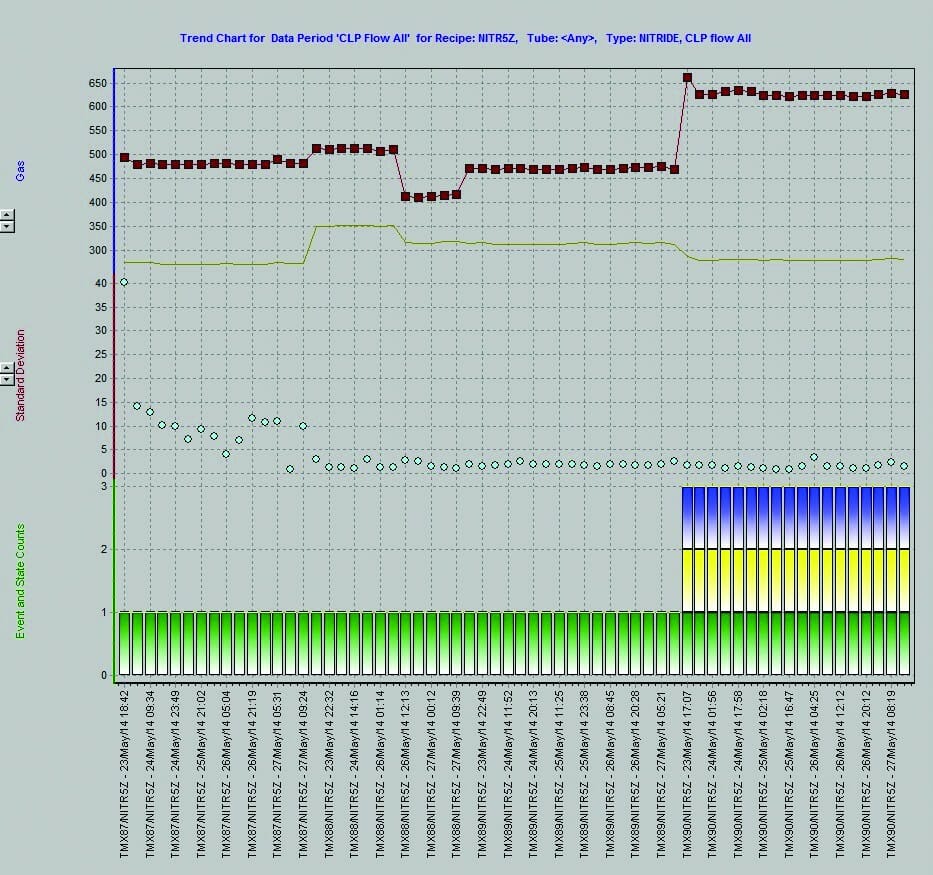

- State-of-the-art data collection and SPC functionality enables customers to increase uptime, tune maintenance cycles and improve equipment performance consistency

Thermco Systems have thermal process tools designed with your emerging technologies in mind

REMOVING OBSOLESCENCE

SUPERIOR, ROBUST TECHNOLOGY PLATFORM

The VTR 7000XE provides customers with a modern, PC-based control system with touch screen GUI interface. In addition to improved ease of operation, recipe generation and graphical interface. This upgrade overhauls the obsolete furnace control, automation and communication systems developed over 20 years ago.

Thermco’s world-class TMX tube controller replaces the obsolete PCE system. Giving users greater flexibility and control over process parameters. The robotic interface

via GUI control offers an enhanced user experience for both manufacturing and maintenance operations. The ACE controller is replaced with an advanced robotic controller connected to the VTR 7000XE control system via high-speed TCP/IP connection.

SPC MONITORING TOOLS

Thermco has the industry’s most advanced SPC equipment monitoring control system. Statistical control is used to monitor and control all critical furnace parameters including temperature, gas flow, pressure, power etc.

The SPC software module predicts when potential problems may occur to allow corrective action. This helps prevent scrap runs by highlighting when processes are starting to drift.