X10, X60 AND X80 MINI FURNACE SOLUTIONS FOR RESEARCH AND DEVELOPMENT APPLICATIONS

OVERVIEW

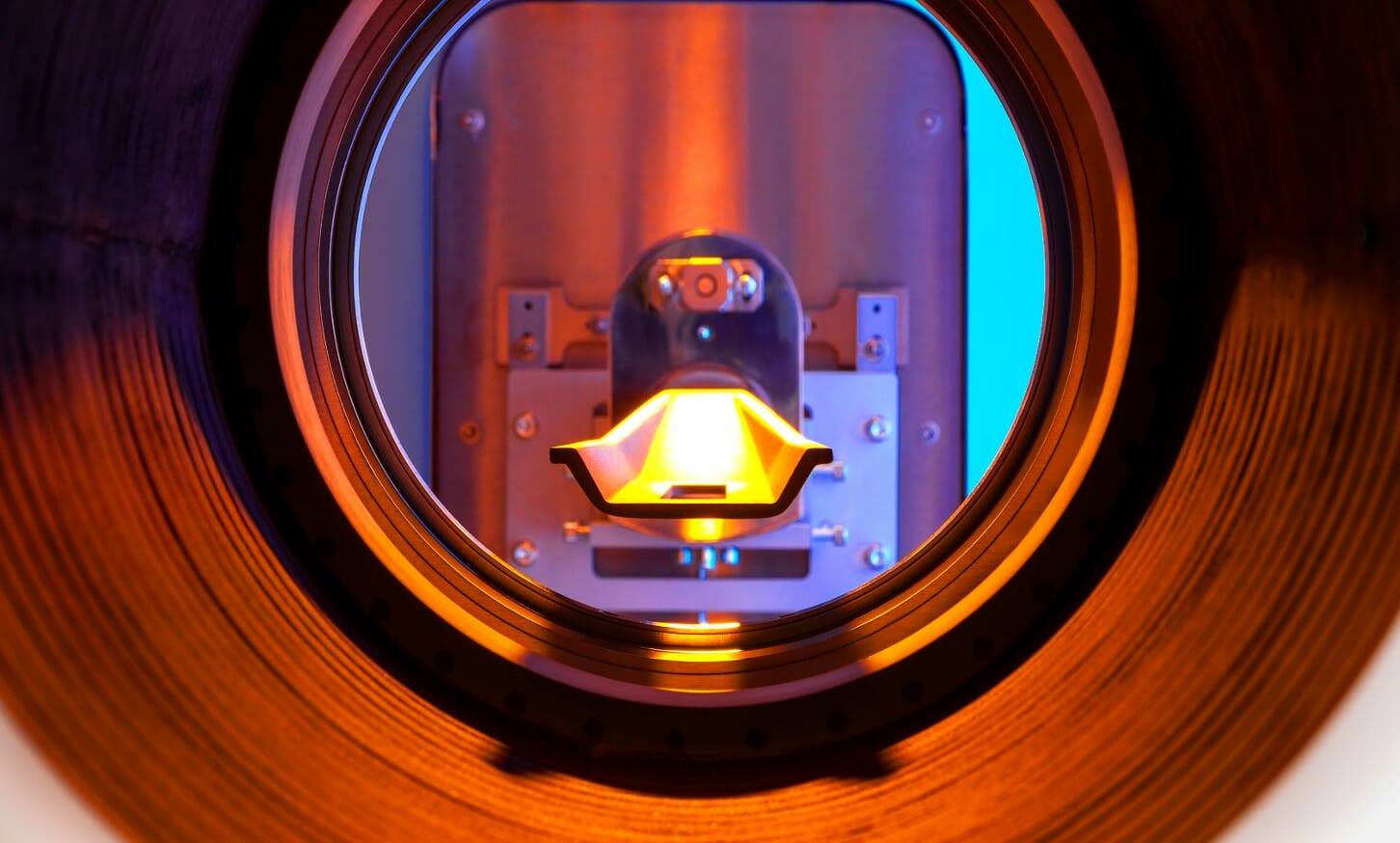

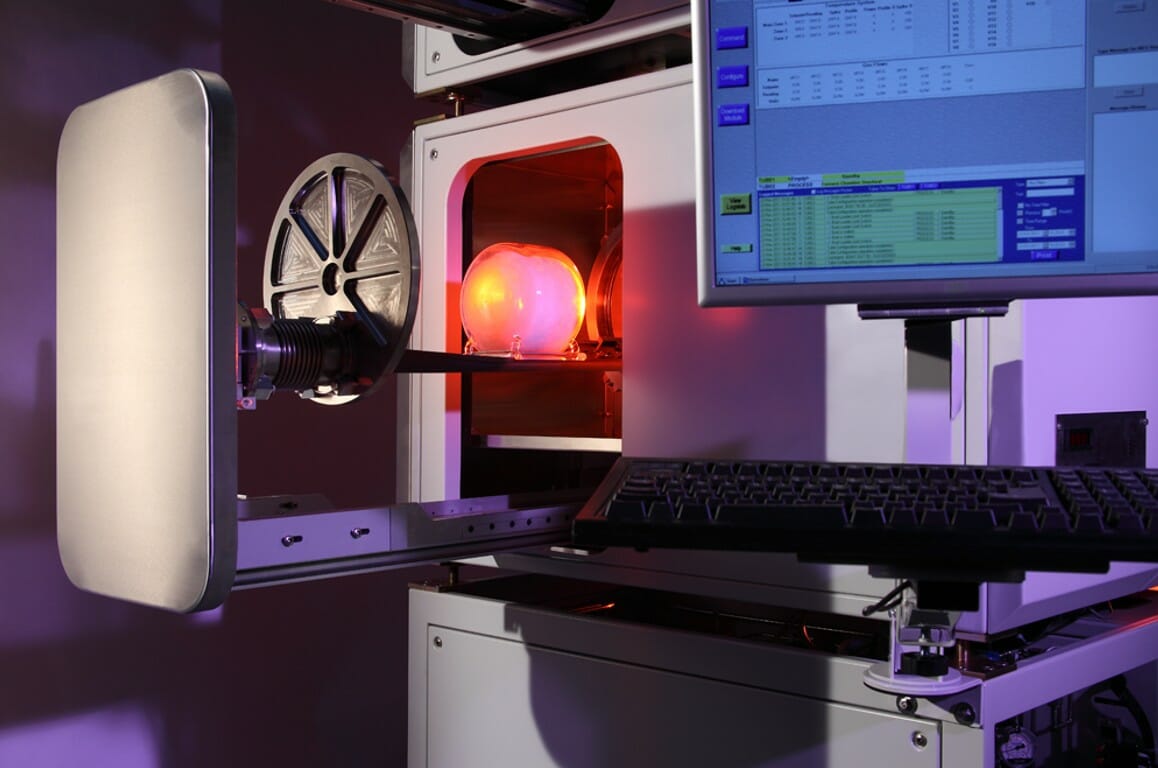

Thermco’s X10, X60 and X80 furnaces have been designed for research and development with a reduced footprint while maintaining precision and leading-edge process capability.

The systems benefit from more than 50 years of experience with Thermco Systems as the leading supplier of furnace technology to the Semiconductor and related electronics manufacturing industry.

With an installed base spanning the globe, our systems are used for leading-edge research by integrated device manufacturers, government departments, universities and educational institutes, for a variety of programs including space exploration, defence, energy, health & medical, and next-gen electronic device process development.

CHARACTERISED

PROCESSES:

- Small footprint with 300mm flat zone for 50 wafers using a standard pitch boat, or 100 wafers configured back-to-back.

- Particle-free cantilever wafer loading system utilizing a linear slide bearing mechanism as standard (X10 option)

- Intelligent control system utilising Thermco Systems PC-MUX & TMX as standard (X10 is PLC-based)

- Superior quality construction and components used throughout, benefitting from the same quality and performance as Thermco Systems full-size production tools.

- Supported substrates up to 200mm.

Thermco Systems have thermal process tools designed with your emerging technologies in mind

THE SYSTEMS

All systems comply with S2-90 and CE mark regulations including EMC.

The systems have manual or automatic cantilever loading of wafers, a choice of control system and can be stacked two high.

The benefits include low cost of ownership on gas, chemical and energy usage due to the small footprint.

X10

PLC control system offering the lowest cost solutions for simple atmospheric and LPCVD processes.

Atmospheric Process

- Dry / Wet (Water bubbler) oxide

- FGA Anneal

- Vacuum Anneal

Manual loading system with dual rod cantilever. It has a touchscreen GUI interface for ease of operation, with data collection capabilities.

*We can provide an optional nitrogen-purged environmental loading system.

X60

X60 with the TMX control system and PCMUX, the same control system as our production sized tools. The X60 supports the full suite of standard processes.

Atmospheric Process

- Dry Oxidation

- Wet Oxidation

- Forming gas anneal

- 100% H2 anneal

- Alloy

- POCl3 (Standard or PV)

- BBr3 (Standard or PV)

- Drive-In

* Others on request

LPCVD Processes

- TEOS

- Nitride

- Low-Stress Nitride

- Polysilicon ( Flat temp,

amorphous or ramped) - Doped Polysilicon ( P or N type)

- Low Temp Oxide ( LTO)

- BPSG

* Others on request