CHEMICAL MANAGEMENT AND DISTRIBUTION

The Thermco chemical management and distribution system is designed to allow the safe delivery of chemicals.

The process begins with the chemical delivery of acids and solvents in bulk drums, typically 25, 40 or 200 litres. These chemical drums are contained within a Chemical Distribution Unit (CDU) with chemical supplied to the point of use by a pump or constant pressurised system.

Larger chemical quantities can be supplied using Industrial Bulk Containers (IBC) stored externally to the CDU.

PRODUCT FEATURES AND OPTIONS

- Aqueous and Solvents

- Bulk tank quantity (1 or 2)

- Capacity: 25 / 40 or 200 litre

- Auto switch-over

- Floor rollers for large tanks

- Day tank chemical ‘polishing’

- Day tank capacity 50 litre

- Waste chemical collection

- Hand gun for DI wash down

- Drain: gravity, pump or aspirated

- Delivery: pressure or pump

- Glove and sample ports

- Off-line redundant pump

- Output pressure indicator

Precise and Safe Delivery of Acids and Solvents

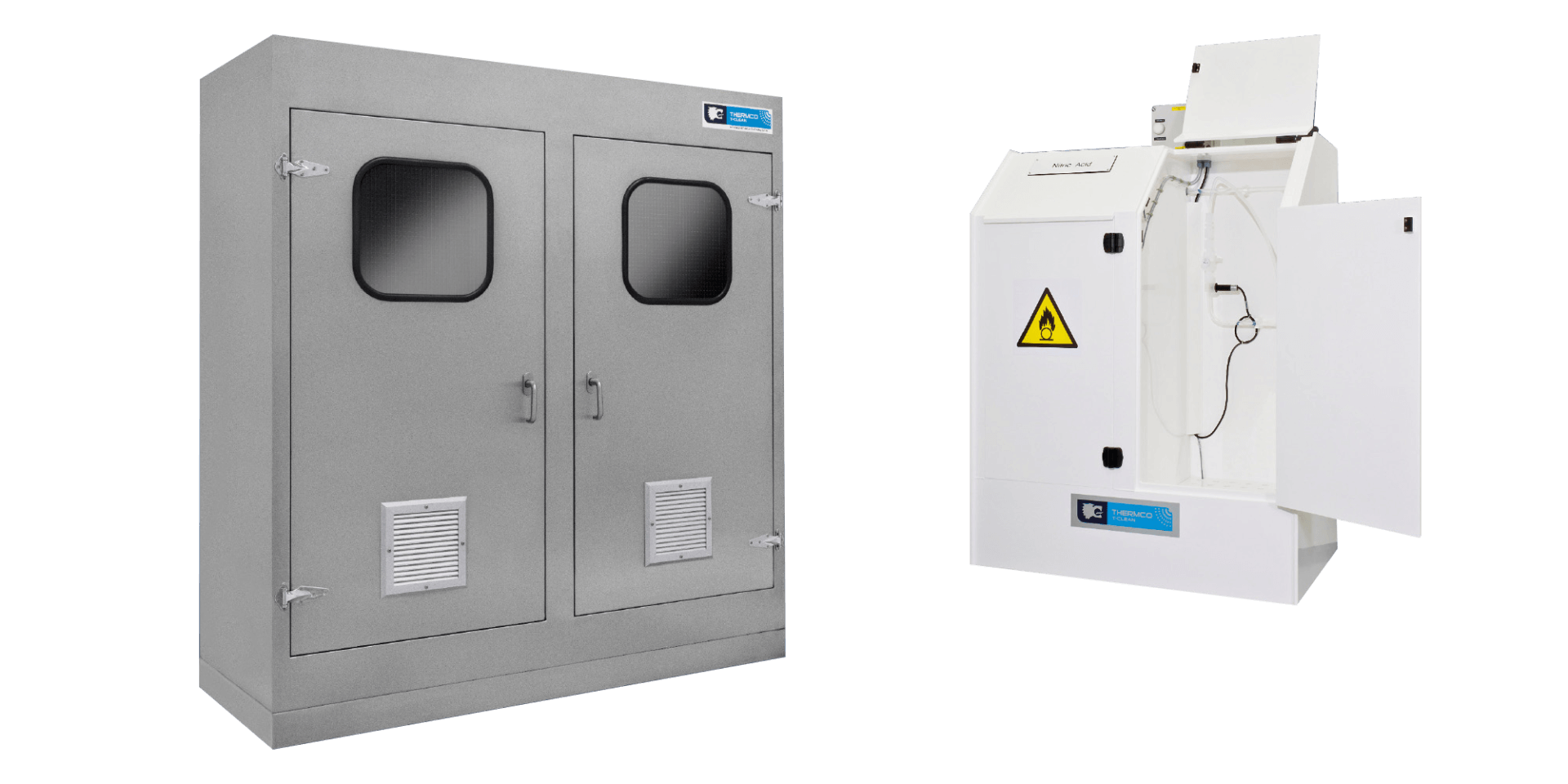

CHEMICAL DISTRIBUTION UNIT

Thermco’s CDUs are intelligent units incorporating a Graphical User Interface (GUI) for setting parameters such as alarm levels and maintenance schedules. These can be interfaced directly to the fab host or to Thermco’s central control system ‘Data Concentrator’ with real-time status.

SAFETY COMPLIANT MATERIALS

Materials used for production are selected to ensure safety compliance. Enclosures for handing aqueous chemicals are polypropylene (PP), with Polyvinyl chloride (PVC) used for equipment requiring fire-retardant properties, such as those with a FM4910 rating. Solvent enclosures are made from stainless steel due to its electrical conductivity, preventing the accumulation of static electrical charges.

HMI AND CONTROL SYSTEM

PLC based control system with 64-bit SCADA designed for process control, manufacturing systems and open automation applications. Compatible with .NET platform and Microsoft operating systems.