Wet Process Systems Including; Cleaning, Etching Wet Benches and Chemical Distribution Systems

Thermco design and manufacture a range of specialist chemical handling products & systems focusing on the Semiconductor, Electronics PV, Fibre Optics, and associated industries. Expertise in fluid handling and substrate automation process solutions.

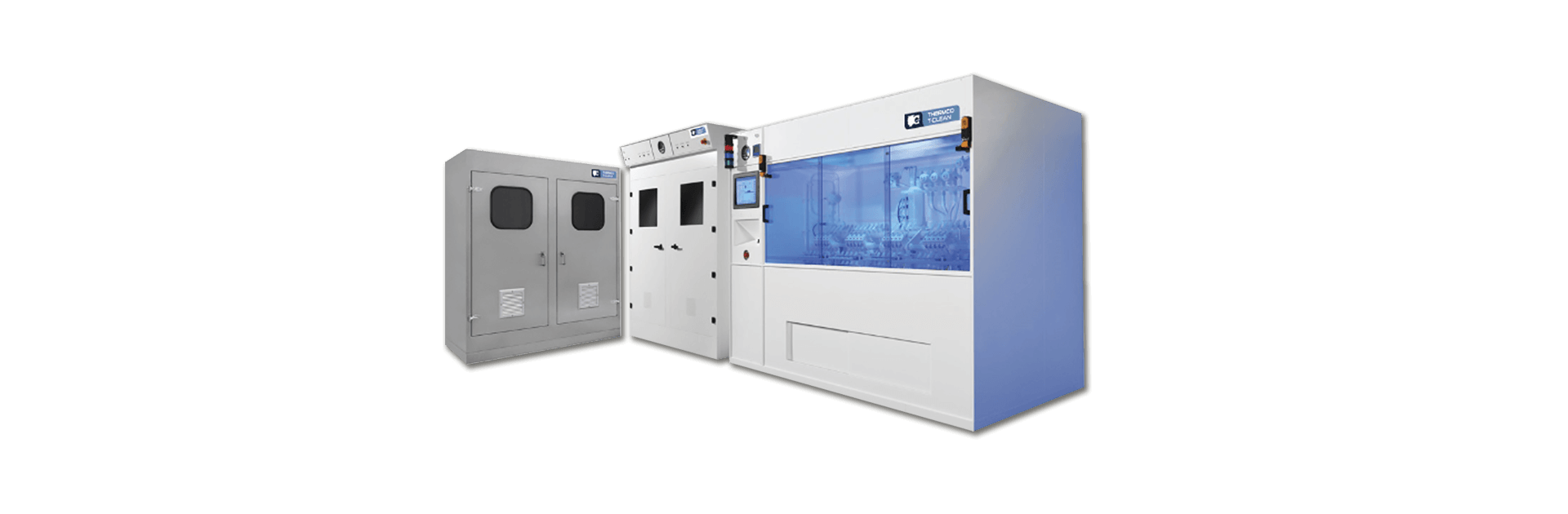

AUTOMATED,SEMI-AUTOMATED AND MANUAL WET BENCHES

Thermco designs and manufactures a comprehensive range of wet benches for semiconductor and related electronic manufacturing processes. From simple manual stand-alone R&D applications, to fully automated production wet benches with connectivity to the fab host via SECS/GEM

BELL JAR & QUARTZ CLEANER

The Thermco Bell Jar Cleaner is specially designed to accommodate large bell jars used on CSD Epitaxy products with an Etch basin to clean auxiliary chamber parts making efficient use of etch chemicals. It is simple to use with its ergonomic design and user-friendly touchscreen interface.

CHEMICAL MANAGEMENT & DISTRIBUTION

Thermco’s Chemical Distribution Units (CDU’s) are intelligent units incorporating a Graphical User Interface (GUI) for setting parameters such as alarm levels and maintenance schedules. These can be interfaced directly to the fab host or to Thermco’s central control system ‘Data Concentrator’ with real-time status.