THERMCO 5000 SERIES PRODUCTION RANGE OF FURNACE SYSTEMS

OVERVIEW

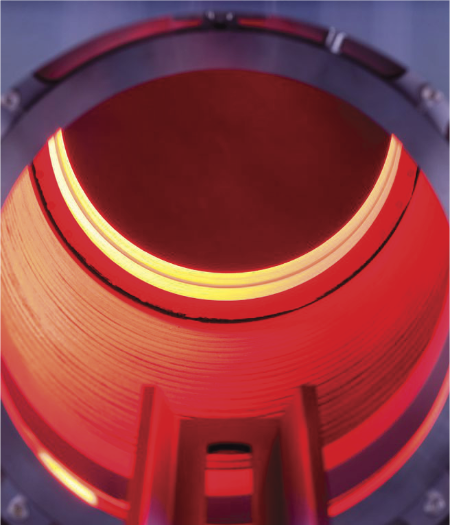

Thermco’s Model 5100 and 5200 Diffusion Furnaces are configurable from two to four-process chamber systems used for processing Semiconductor, PV, LED, Nano and MEMS substrates up to 150 mm in diameter.

5100 series has a 750mm flat zone and the 5200 series has a 1,100mm flat zone leading to greater wafer processing capacity for the 5200. The 5100 and 5200 can be interfaced with a wide range of automation solutions, such as elevators and fully automatic cassette-to-cassette automation packages.

The furnace mainframe is constructed of welded and formed cold rolled steel, painted with industrial-grade water-based enamel paint. Parts and components that are subjected to elevated temperatures are constructed from stainless steel.

CHARACTERISED

PROCESSES:

- Silicon Nitride

- Low-Stress Silicon Nitride

- Ramped Temp Polysilicon

- Uniform grain Polysilicon

- TEOS

- LTO (Doped / Undoped)

- BPSG

- High-temperature Oxide (HTO)

- High Vacuum H2 Anneal

- Dry Oxide

- Wet Oxide

- POCl3 or BBr3

- Forming gas anneal

- High-temperature drive in

- Alloy or temp anneal

- 100% H2 anneal

- FGA Anneal

- CNT growth

- Graphene growth

- Others available on request

Thermco Systems have thermal process tools designed with your emerging technologies in mind

CONTROL SYSTEM

The furnace is controlled by the industry-leading Thermco TMX controller, recognised as one of the most flexible and reliable furnace control systems available with an installed base of thousands of units. The TMX control system and PCMUX combines the tried and trusted recipe and system control formats of earlier generation TMX products with new updated, reliable software on PC-based hardware with improved graphics, control and AI functions. The system comprises one MUX computer for recipe generation and status overview and one control computer per tube.

FURNACE PERFORMANCE

- 3 independently controlled heating zones

- Isolated secondary voltage power

- Zero Cross Over full phase SCR firing

- Balanced power loading

- Thermal safety circuits and SCR cooling fans

- Optional fast ramp (up to 25°C/min), fast cool system (up to 20°C/min)

OPERATION RANGES:

- Operating temperature range: 200°C to 1350°C

- Low to mid-temperature operating range: 200°C to 900°C

- High-temperature operating range: 750°C to 1350°C

- R-Type TCs for low to mid-temperature range

- B-Type TCs for high temperature range

- Spike and profile temperature control thermocouples

- Cold junction compensation

- Flatzone, 5100 : Up to 750 mm

- Flatzone, 5200 : Up to 1,100 mm

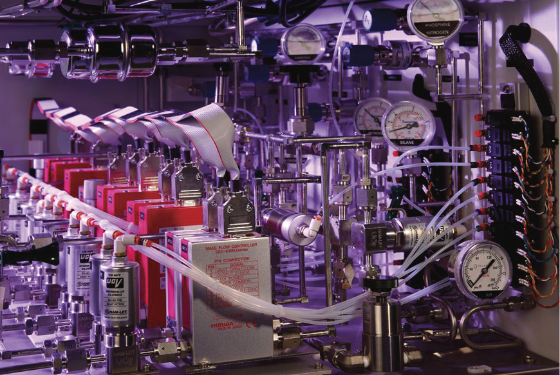

GAS SYSTEM

- High-quality, ultra-clean gas systems with POU filtration

- Regulation and filtration of incoming bulk gases

- Maximum 8 Digital or analogue MFCs

- Orbital welding and VCR fittings

- Nupro air-operated valves and check-valves

- Systems tested to 10-8 ATM cc/sec

- Leak checked to 10-7 cc/sec