THERMCO-EPITAXY EPIPRO FAMILY OF SILICON EPITAXY REACTORS & DEPOSITION SOLUTIONS

The EpiPro family of systems meets the industry’s need for high throughput processing with a low cost of ownership for epitaxial processing using Epitaxy Reactors

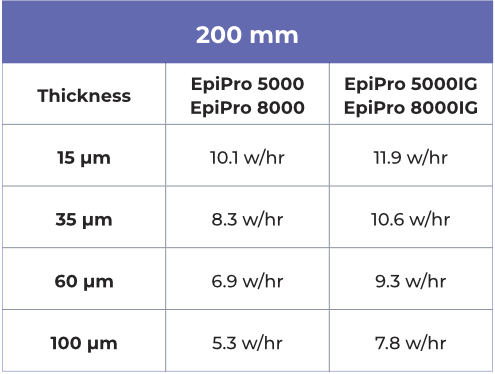

Dual station batch silicon epitaxy deposition solutions designed to meet today’s demanding production requirements offering both manual loading/unloading and fully automatised wafer handling solutions.

Combining leading-edge technology, and process capability with field-proven capability.

PRODUCT FEATURES:

- High Process Flexibility

- P and N doped material

- Substrates from 100 to 200mm

- Wide EPI Layer thickness

< 5 μm to > 100 μm - EPI Layer Resistivity from

0.02 Ω cm to 50 Ω cm - Dual-process chamber systems

- IG systems with dual RF supply for induction heaters

- Low Cost of Ownership

- Unique dopant injection system

- Patented chamber features

- EpiPro 5000: Manual solution

- EpiPro 8000: Automated solution

Thermco Systems have thermal process tools designed with your emerging technologies in mind

EPIPRO FAMILY

EpiPro 5000:

Manually loaded/unloaded. Dual reactor with inductive coil heating systems and single switching RF generator source.

EpiPro 5000IG:

Manually loaded/unloaded. Dual reactor with inductive coil heating systems and dedicated RF generator source for each reactor for higher throughput.

EpiPro 8000:

Automated loaded/unloaded. Dual reactor with inductive coil heating systems and single • switching RF generator source.

EpiPro 8000IG:

Automated loaded/unloaded—dual reactor with inductive coil heating systems and dedicated RF generator source for each reactor for higher throughput.

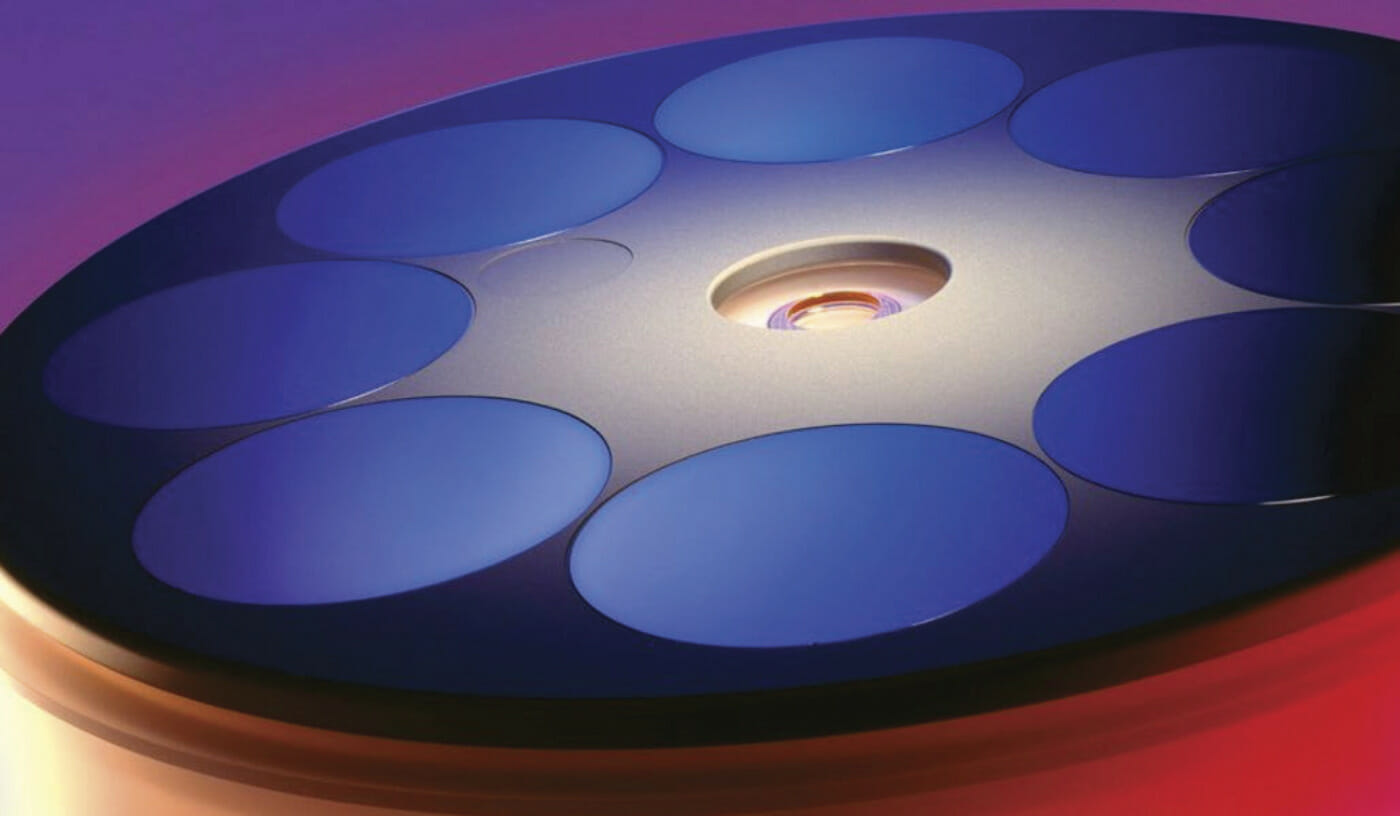

Upgraded PLC control system with Windows OS touch screen GUI. Now offering SECS / GEM interface.

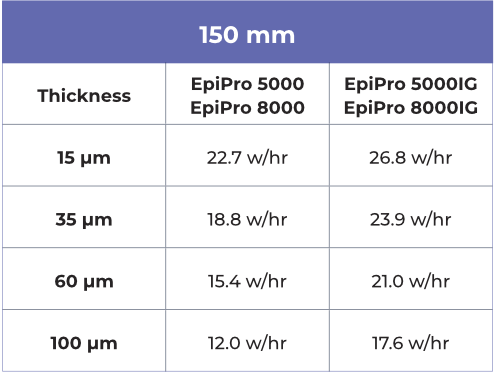

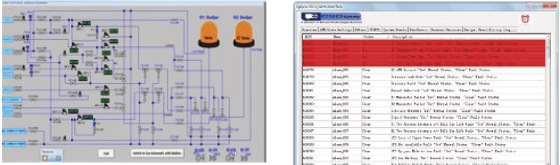

TYPICAL THROUGHPUT COMPARISON: