Overview

Following the donation of a diffusion furnace to the university by SEMI (the industry trade body) member company Thermco Systems, based in West Sussex, UK, the Photonics Lab in the university has been transformed into a semiconductor laboratory capable of making simple electronic devices such as capacitors, diodes and transistors. In the first instance, it will be used as part of 2023 courses in Chemistry and Physics to make students familiar with the basic principles of manufacturing the devices which integrated circuits (“chips”) are fabricated from. It will also hopefully inspire fresh talent to join what is truly a global industry. In addition, it is also capable of providing training SEMI members’ employees in the techniques used in the industry. In these twin roles, it has the potential to provide a vital bridge between academia and industry.

Achievement

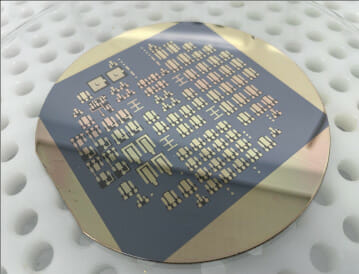

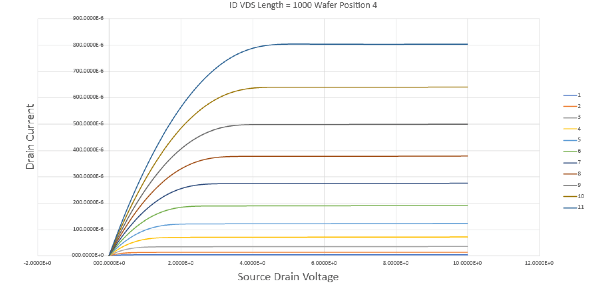

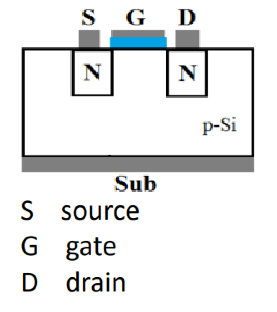

The very first wafer, a 3-inch disc of silicon (“wafer”) was successfully processed through 23 individual process steps to form a MOSFET transistor, originally developed by TU Dublin who have helped at every step of the way. This is the finished wafer produced by 4 project students from Chemistry and Physics under the direction of Andy Murray, the Lab Supervisor; each group of 3 contacts represent the source, gate & drain of an individual transistor:

To our amazement, all the transistors on the wafer worked correctly, not bad for a first attempt and testimony to the excellent recipe we were given…

Going Forward

- I have shared the good news with SEMI, Thermco, Intel/TU Dublin and Edwards.

- Matt Smith has submitted a bid for Innovate UK funding for semiconductor courses.

- Laith Altimime, head of SEMI Europe, will publicise amongst his member companies, including the opportunity for staff training.

- I am putting Edwards’ university liaison person Sarah Morteo in contact with Jaap Velthuis at the university to discuss staff training opportunities.

Thanks and Acknowledgements

Basically to everyone involved in any capacity in this project!

And especially:

- Edwards, who, when I was an employee, enabled my liaison role with the university and SEMI.

- Thermco Systems for the generous donation of the diffusion furnace which enabled the cleanroom to function as a semiconductor lab.

- Intel and TU Dublin, who helped convince me this would be possible (by example), and have assisted this project at every step of the way by sharing information, recipes and expertise.

- SEMI, for helping originate the initial concept during a visit to the university to discuss the 2018 Talent Forum, and actively supporting the ideas into fruition.

- And of course the University of Bristol for making the concept a reality, in particular, Jaap Velthuis and Andy Murray.

I look forward to continuing supporting this activity in future as it develops and matures,

Prof. Mike Czerniak